You should also know that the North Haven, Conn., manufacturer has been producing gas-operated semi-automatic shotguns since 1986, beginning with its Model 1000 hunting gun that was licensed, branded and sold under the Smith & Wesson logo. In 1998, six years after the introduction of its Model 9200 semi-automatic, Mossberg produced the 9200A1 Jungle Gun—an 18.5″-barreled semi-automatic—in the hopes of satisfying the Department of Defense’s call for a “Joint Service Combat Shotgun.” It didn’t win the contract, but it did pave the way for the 930 series first produced in 2005—one year after releasing the 3 1/2″-chambered Model 935.What do all current Mossberg shotguns have in common? They have tang-mounted safeties, a reputation for reliability and blue-collar price tags. As of this writing, you can buy a Mossberg Maverick 88 pump (parts sourced from Mexico but assembled in Texas) over the counter for $190, or a Mossberg 500 (made in USA) for around $250. Name a better value in all of the consumer world, and I’ll pick up your bar tab.

The only downside for Mossberg is that once a company dominates a specific market—in this case, pump shotguns—it can be difficult to break out of that mold. And the 930 didn’t do it—it simply didn’t stand out from a dozen other companies’ gas-operated semi-automatics in a meaningful way. Mossberg felt it had to stick to its affordable, blue-collar roots, so while the 930s are perfectly serviceable, they are necessarily a little rough around the edges compared to higher-priced shotguns such as Brownings, Benellis and Berettas.

For under $500, I believe the 930 is the best semi-automatic going, but I’m afraid not all that many shotgunners know about it, because budget guns don’t garner the limelight as do the slick flagships that dominate competitions and magazine covers.

So, in 2018, Mossberg decided to challenge itself, indeed the entire market, to remain relevant in the semi-automatic shotgun category. But to accomplish that goal during what I call today’s golden era of defensive and tactical shotgun design, Mossberg had to do something impressive enough to turn heads. Who did they turn to? Oh, just a guy by the name of Jerry Miculek.

In this writer’s opinion Jerry Miculek is the greatest all-around action shooter in the history of the world. While Jerry opines that this designation should go to Walter Walsh, it’s undisputable that Jerry is one of the nicer and most gun-knowledgeable guys you’ll ever find. In Jerry’s line of work—where fractions of a second separate top shooters and one jam can mean the difference between first place and no place—his tools must work all the time, every time.

His guns must be fast and cannot be a hindrance whatsoever. Frankly, when Mossberg first signed Jerry back in 2012 to use its 930 exclusively for competition, I could see how Miculek might have balked at using an unproven gun that, as I mentioned, is a little rough around the edges. That’s especially true if it could possibly cost him a match—even if he’s getting paid to use it. So, I asked him about it.

“Tom Taylor (then Mossberg’s CEO) told me the 930 was a good gun, and Tom doesn’t lie. And sure enough, the 930 is a good gun. It’s rugged; it contains big pieces and hardly ever breaks,” Miculek said. “On many long-action gas guns, when the gas system reciprocates the rings come out of the piston and then they must go back into the piston and therefore they break frequently. The 930’s rings stay captured in the piston. It’s really fast and simple. I’ve never broken one.”

But as anyone who’s ever seen Jerry in action knows, his competition 930s were far from stock. A maintenance mechanic by trade and a gunsmith by necessity, Jerry modified and whittled on his competition 930s until they were as slick as Fonzie’s hairdo. Specifically, Miculek tricked out his comp shotguns by Mag-Na-Port(ing) the barrels, bolting on brackets for speedloading sticks, Dremeling out the gas ports and snipping a coil off the sear springs to reduce trigger pull weight slightly.

Indeed, nearly all guns in the open division of professional shooting exhibit heavy modification. Winning repeatedly with the 930 was evidence of the platform’s capability, so when Mossberg approached Miculek in 2018 to collaborate on a new line of competition shotguns with both internal and cosmetic upgrades, Jerry knew exactly what the new gun needed in order to be a winner right out of the box.

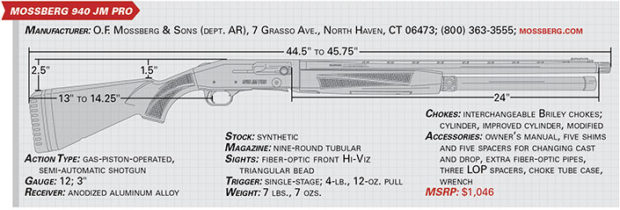

“Mossberg engineers came over to the house, and we shot on the range, then we came inside and I showed them all kinds of stuff, and they showed me the feedback they were getting from customers. We knew we could make a much more user-friendly shotgun,” Miculek said. What resulted 18 months later was Mossberg’s new 940 JM Pro, a nine-round-capacity, gas-operated gun with a 24″ barrel and all the necessary upgrades to make it race-ready. To date it’s by far Mossberg’s best shooter. Most amazingly, it retained its blue-collar price tag.

Internal Upgrades

The 940’s gas system was overhauled, including the piston and sealing ring system, spacer and pusher assembly so it would run more efficiently with a wider range of ammunition. The system features two large gas ports in the gas cylinder welded to the underside of the barrel. A very robust, short-stroke gas piston assembly accepts the burst of gas from the fired shell and violently slams a mere 5/8″ rearward, moving the innovative spacer tube, pusher assembly and finally the bolt assembly rearward to cycle the action.

“We changed the way the gas system is fitted to the piston,” Miculek said. “I equated it to a ceramic seal on a sulphur pump, and said to the engineers, ‘Why don’t you make it like a mechanical seal?’ And they came up with a really trick gas piston that will take away some of the problems for people who do not perform any maintenance.”

The 940 is touted to run 1,500 rounds without cleaning, compared to the 930’s 500. Jerry—whom I take at his word despite his obvious alliance—says it’s legit, although he has a tough time understanding people who don’t understand that guns, like all machines, need routine cleaning and maintenance. “The 940 can run 1,500 to 1,600, depending on the ammo. Due to the short-piston design, it can handle different loads without too much of a gas compensating effect to keep the bolt velocity relatively close. That’s a big reason why the long-cycle gas guns are so finicky with various types of ammo,” he said.

–

The inside of the piston features machined grooves, which I believe perform like fluting to reduce friction as it slides back and forth on the magazine tube. And in addition to the new piston and sealing rings that fit so tightly it feels almost as if it contains a rubber O-ring, which it does not, I believe another key to the 940’s enhanced reliability is owed to its innovative spacer tube.

This 3.5″ aluminum cylinder that rides on the magazine tube between the piston and the pusher assembly also features grooves to reduce surface area and to allow carbon fouling and grime a place to go rather than just adding friction during its movement around the magazine tube. Jerry says that much like a car that is started will often leak water from its tailpipe, an amount of condensation occurs between these metal parts unless the gun is fired until it’s very hot. The grooves in the 940’s spacer give this moisture somewhere to go, while its perforation allows air to dry it out so it doesn’t rust or foul as much as others.

The 940’s trigger assembly is removable via two pins; its spring-powered hammer is released by a sear and visible spring on top. The 940’s trigger, like my 930’s, averaged 4 lbs., 12 ozs.—which is excellent. Two seldom-noted features of this gun are its cocking-indicator pin that juts from the inside of the forward trigger guard, so shooters can feel if the gun is cocked without looking, and an overtravel set screw on the trigger so even trigger mashers can get the fastest trigger reset possible.

The 940’s bolt assembly mimics the 930’s. It consists of a hollow bolt, the slide on which the bolt rides within the receiver, a pivoting locking lug nestled within the bolt, a spring-loaded extractor, a transcending firing pin, charging handle and the rattail-like link that enters into the recoil spring tube in the stock.

External Upgrades

Jerry and his protégé, and daughter, Lena Miculek insisted on a shotgun that would fit a wide range of shooters. After all, fit—including drop at comb, length of pull and cast—is critical to a shotgun’s point of aim/point of impact, felt recoil and overall shooter satisfaction. To accomplish this, the 940’s recoil spring and spring tube had to be shortened to allow room for a modular, user-adjustable stock. The 940 comes with five spacers and shims to alter drop at comb/heel and cast on/off, as well as a modular buttpad system that makes the gun’s length of pull adjustable from 13″ to 14¼”. In this way, the 940 is suitable for little Lena on up to shooters over 6 ft. If you buy this shotgun, I strongly suggest taking the time to remove the stock and experiment with the shims to find the best fit for you.

Secondly, Lena and Mossberg designed a fore-end that was conducive to speedloading where two or four (called quad-loading) rounds can be clutched with one hand and loaded into the magazine tube in under a second by sliding the palm across the loading port while using the side of the thumb to force two shells into the magazine in one motion. You have to see video of this difficult technique to appreciate it, but in order to perform it, the bellies of the receiver and the fore-end must form a smooth transition so the hand can slide forward fluidly.

So engineers trimmed the fat on the 930’s fore-end to make it slimmer, then cut a U-shaped notch into the receiver end of it to accommodate a fore-end retainer piece that forms a smooth confluence while holding the receiver, the magazine tube, the fore-end and the bolt rail in place. Then the loading gate was elongated, the gate’s spring was lightened and the gate cutout was eliminated to spare shooters from dreaded thumb pinch. As such, I’m not sure there’s a shotgun better-suited for quad-loading straight from the box.

The 940 JM Pro features oversized controls to reduce fumbling. I especially like the bolt/shell release button that pivots backward and is much easier to activate, thanks to leverage, than traditional push buttons. The bolt release button also serves another nifty purpose; with the gate manually depressed, a push will release a shell from the magazine tube so the magazine can be emptied—or a single shell replaced—without cycling each shell into and out of the chamber.

–

Its safety is, of course, located on the tang. This metal, stepped hallmark is anodized golden yellow, just like the bolt/shell release button, choke tube rings, charging handle, spacer tube and magazine tube extension nut for aesthetic effect. The anodization of the magazine tube follower, however, serves more than an aesthetic purpose; it alerts the shooter that the magazine is empty by a mere glance.

A nine-round extended magazine tube that rides parallel to and below the gun’s 24″ barrel comes standard. If the 940 JM Pro, like all extended magazine shotguns, has one weak link, this is it. You see, a nine-round magazine requires a thin spring approximately 34″ long. Springs eventually weaken with use; so, if the gun does start to misfeed after many rounds, suspect this magazine spring first. On a more positive note, the magazine tube does not utilize clamps to hold it to the barrel, a feature that typically makes such guns more accurate with slugs, as does the front triangular Hi-Viz sight that allows finer aiming than a round bead.

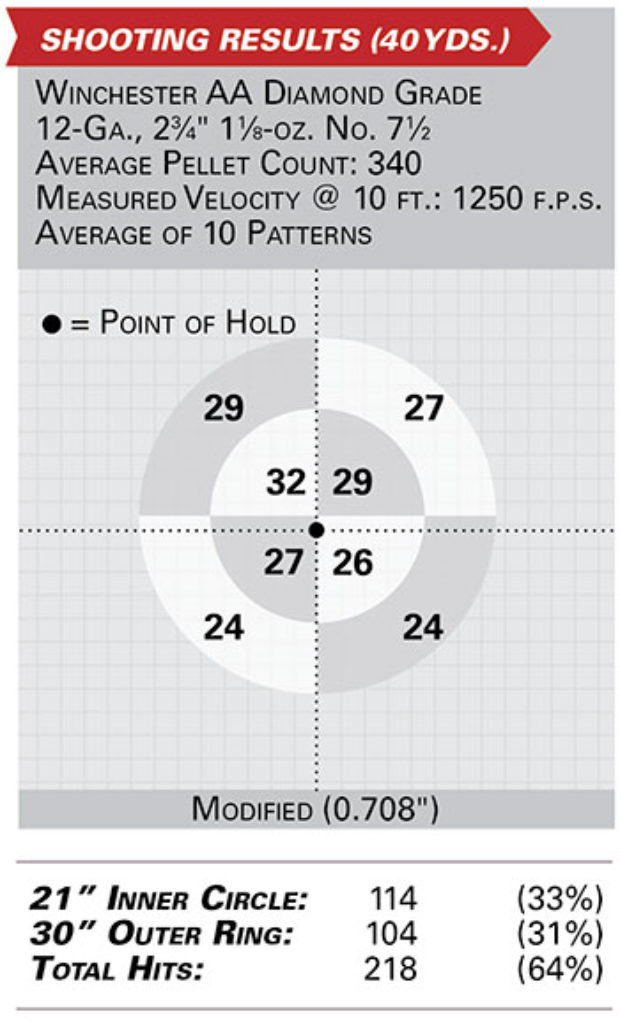

Finally, the machined aluminum receiver is anodized a matte Tungsten gray, and is drilled and tapped for an optic rail. The shotgun comes with three (cylinder, improved cylinder and modified) premium Briley extended choke tubes that’d cost around $100 if you were to purchase them separately. They pattern great and represent a tremendous value-add.

Field Notes

After shooting the 940 JM Pro profusely, I’ve developed a few opinions. First, it’s likely the best full-length semi-automatic shotgun you can buy for around $1,000, and certainly for its $900 real-world price. It comes up to my eye naturally; instantly I hit flying targets without conscious thought, indicating that it shoots where I look. I like it almost as well on the skeet field as I do on the 3 Gun range. It’s silky to load, thanks to its fore-end contour, non-pinching gate and finger-friendly springs, and I found I can let a shell ride on the carrier, a trick that allows this gun to hold 11 rounds in total.

All its controls are wonderful, and it patterned uniformly. What was most striking however, was this gun’s surprising recoil-mitigating properties, especially when you note its overall weight of only 7 lbs., 7 ozs.—which is insane knowing it comes with a nine-round magazine tube. Most competitive shotguns in this category weigh at least a pound more, and so I was afraid the 940’s recoil would be considerable. But because there is no magic to recoil mitigation, I can only account it to three things: 1. The gun’s gas system and return springs are efficient at soaking up recoil. 2. The gun fit me well. 3. Its soft rubber, collapsing buttpad works well.

I could not get the gun to jam, including during a break-in period. It even fed 1-oz. target loads—a feat plenty of 12-ga., 3″-chambered autoloaders fail to do. I love the classy (and rust-resistant) anodization and the gun’s overall looks. It’s also offered in an urban camouflage pattern; either gun would serve as an excellent choice for home defense. Jerry says the only thing he’d do is add a flashlight to it.

If there is one aspect that could be improved, however, it would be the stock material. It’s a cheap-feeling, hollow, hard plastic; while it is durable and functions fine, one area where some of the more expensive brands are beating Mossberg is in their stock material that is softer and not as brittle-feeling.

And while I’d like to see a soft rubbery comb insert too, I realize these non-essential bells and whistles drive up prices—and that’s a big reason why the aforementioned guns often cost $500 or more higher than the 940. Finally, I wish it had a mid-bead atop its vent rib, just to make aiming at stationary targets more precise.

All in all, I’m amazed at the 940 JM Pro’s value, and I feel sure after shooting it that the platform will replace the 930 in the near future with models for every application, including turkey/predator, upland, waterfowl and tactical.

When it does, not only will the professional 3 Gun circuit be challenged, but every semi-automatic shotgun manufacturer, as well as guys in duck blinds who think their $1,500 autoloader is the best largely because it costs more. Jerry believes that if any gun can be the catalyst that branches Mossberg from its predominantly pump-gun reputation, the 940 is it. And I’ll take his word on it.